Soletair Power (Finland) has actually established a relatively special option for drawing out co2 (CO2) from constructing ventilation systems to assist accomplish carbon net absolutely no and even carbon unfavorable structure tasks. The business utilizes temperature level vacuum swing adsorption (TVSA) to segregate CO2, prior to restoring the adsorbent by ‘swinging’ to a vacuum. Soletair’s TVSA has the ability to record CO2 with 99.9% pureness, utilizing less than 100 Deg C as the regrowth temperature level. The procedure is reliant on precise, dependable measurement of temperature level, humidity, and CO2 utilizing innovation established by instrumentation company Vaisala– author of the post that follows.

Structures and building and construction are accountable for 37% of the world’s CO2 emissions, so enthusiastic objectives have actually been developed to decrease this figure throughout both building and construction and operation– the supreme goal is to accomplish carbon net absolutely no structures. There is likewise pressure from regional and industry-specific guidelines along with more comprehensive, international requirements like the Paris Arrangement, which needs a 50% decrease in CO2 emissions by 2030.

Soletair Power, established in 2016, revealed the capacity for innovation to decrease a structure’s carbon emissions by catching CO2 from its ventilation system and utilizing it in the production of fuel or concrete, for instance.

Why capture CO2 from structures?

CEO Petri Laakso describes the numerous advantages of Soletair Power’s options. “Recording CO2 from a structure’s air, whether that be its inlet, exhaust, or flowed air, minimizes its general CO2 emissions. Our system likewise provides cost-reduction, staff member wellness, and sustainability advantages. For instance, with CO2-lean air entering the structure you can decrease ventilation levels– which saves money on heating, cooling, and energy, additional decreasing functional CO2 emissions. Lower CO2 levels inside workplaces and property structures likewise add to much better health, wellness, and staff member efficiency.

” To record CO2, the air requires to be moving and ventilation systems do this work for us, and the air in structures likewise tends to be around 20 ° C, which is the maximum temperature level for our procedure.”

In addition to catching CO2 from the air travelling through heating, ventilation, and cooling (HEATING AND COOLING) systems, Soletair Power has actually likewise established an indoor CO2-filtering air cleanser for conference room and smaller sized office, and an outside CO2 capture system. “Our outside gadget is extremely comparable to the HVAC-integrated one, however with a real estate around the system,” states Petri. “We have one such system in Duisburg, Germany, which is set up outdoors to record as much CO2 as possible. The CO2 is then utilized by the business as a basic material for different commercial procedures.”

Are carbon-negative structures possible?

A significant fringe benefit of Soletair Power’s option is that the recorded CO2 can be utilized for other applications, consisting of concrete production. “For concrete, the recorded CO2 is utilized to produce calcium carbonate, so you have the possible to accomplish unfavorable emissions when the CO2 is locked away from the environment. This is one method we can assist structure owners to accomplish net-zero emissions for the structure’s life time by making up for construction-related and functional emissions,” states Petri. “Carbon-negative structures will likewise provide substantial expense savings, implying our systems can offer a roi within simply a couple of years.”

Attaining net absolutely no is no mean accomplishment however, and the capability to do so can depend upon different regional elements, consisting of how the power and heating for the structure is produced. “To make a structure into a carbon sink you require its electrical power to be sustainable and the heating from a source that reduces emissions,” Petri describes.

Soletair Power is presently dealing with a number of tasks to produce carbon net absolutely no structures. “These tasks are utilizing different sophisticated steps to decrease CO2 emissions throughout structure construction and operation; sometimes, our option is the last touch that ideas the emissions over onto the unfavorable side, and we need to have some amazing outcomes to share in the coming years,” Petri states.

Transforming recorded CO2 into sustainable fuel

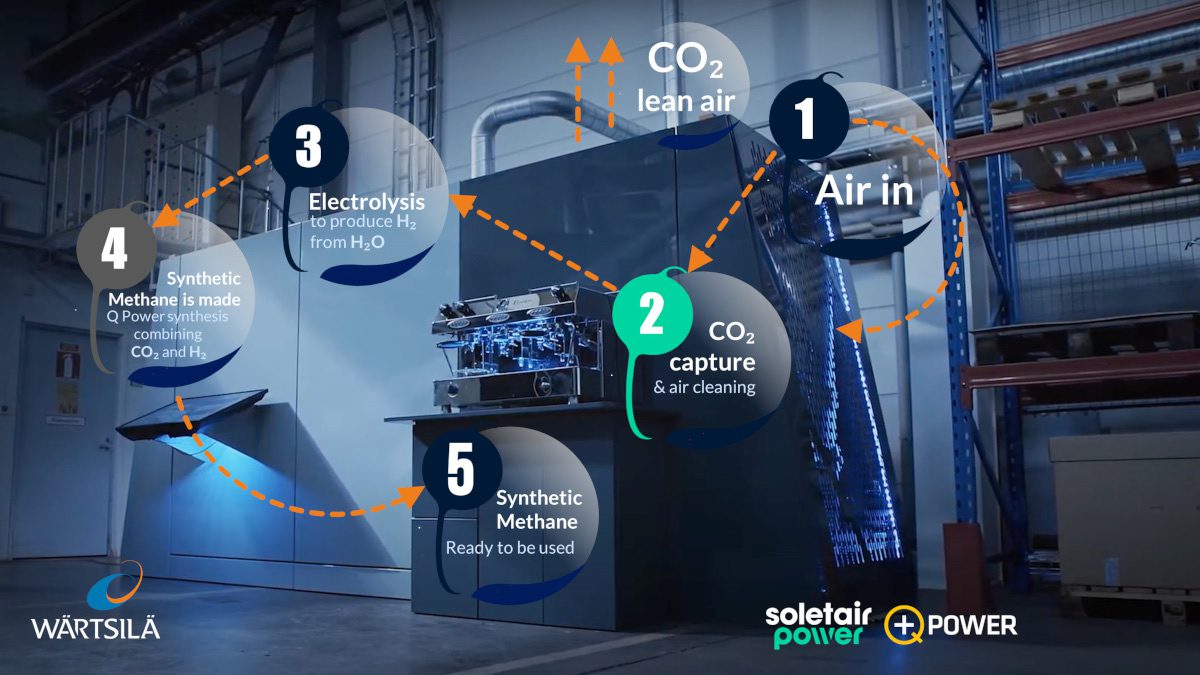

In fall 2018, Wärtsilä, an international leader in ingenious innovations and options for the marine and energy markets, approached Soletair Power about utilizing drawn out CO2 to produce fuels, prior to coming aboard the task with a seed financial investment in April 2019. The cooperation produced the world’s most compact gadget that utilizes air to produce fuel. The Power-to-X presentation system, which was showcased at the Finland Structure at Exposition 2020 in Dubai, utilized sustainable power and CO2 from the surrounding air in addition to hydrogen from water to produce artificial methane, which was then utilized to power a coffee device for tradeshow visitors. The business have actually likewise teamed up on the advancement of an HVAC-integrated system that records CO2 from the inlet air at Wärtsilä’s Sustainable Innovation Center in Vaasa and materials CO2-lean air to the structure.

Precise sensing units are a crucial foundation

The objective of the CO2 capture system is to decrease a structure’s energy intake while keeping the exact same level of air quality inside. “Our system keeps the CO2 in the structure at a low level, so that the ventilation can run at extremely low levels in a demand-controlled mode. We require to be able to properly determine the CO2 information to figure out just how much the system is catching, which is where Vaisala’s sensing units enter into play. In addition to CO2 sensing units, our innovation likewise utilizes sensing units for humidity and temperature level at different points while doing so.”

Soletair Power utilizes the duct humidity and temperature level transmitter HMD60, the CARBOCAP ® co2 transmitter series GMD20, the CARBOCAP ® co2, temperature level, and humidity transmitter series GMW90, and Vaisala’s portable CO2 meter GM70 to take these readings.

Petri describes the factors behind picking Vaisala: “It was necessary for us to utilize superior devices in all of our systems. We formerly utilized less expensive sensing units from somewhere else, however we discovered that the long-lasting stability of the devices was doing not have, which suggested that we could not ensure precise information as the devices aged. Mindful of Vaisala’s track record for customer care and precise dependable measurement options, we for that reason transferred to Vaisala.”

Petri likewise highlights the significance of dependable devices in acquiring insights from measurement information: “The efficiency of our chemistry-based option is impacted by different elements consisting of ambient conditions, so if you do not have dependable information, it’s tough to evaluate why those modifications have actually taken place.”

Soletair Power’s future strategies consist of establishing the TVSA innovation to make the CO2 capture systems more compact and enhance the sustainability of their operation. “We anticipate to continue our cooperation with Vaisala, and as our option establishes, we will likely require the assistance of their specialists on which sensing units to select and how to adjust them to work efficiently in altering climatic conditions,” Petri describes.

With international urbanisation continuing apace and emissions guidelines ending up being ever more stringent, the requirement for ingenious options in structures and building and construction is set to grow– and with disruptive leaders like Soletair Power leveraging Vaisala’s steady and dependable measurement innovations to take huge advances, the future is brilliant.